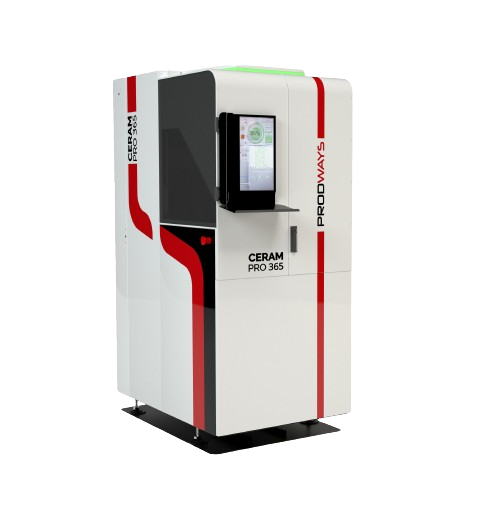

Materials » MOVINGLight® DLP ceramic resins » SILICA SICAST 1200

SILICA SICAST 1200

An innovative materials for investment casting

Silica resin is specifically designed for investment casting. SINTX’s SICAST Resin has 8 years of engineering behind it and was one of the first resins developed for use in the investment casting of super alloys. Typically, the thickness ranges from 50 to 100 um. It offers good green strength and minimal densi- fication on sintering, improving leachability. This resin can be customized for your particular alloy and casting conditions.