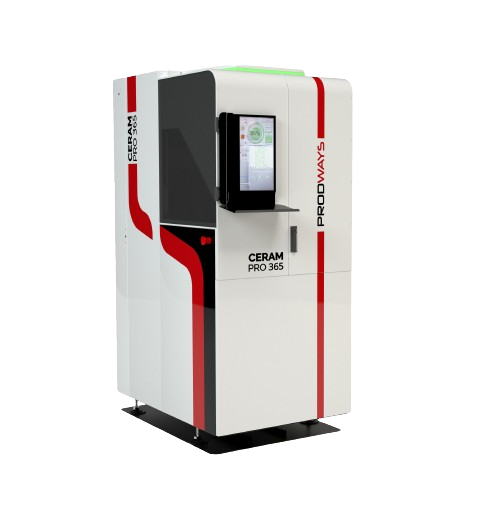

Materials » MOVINGLight® DLP ceramic resins » ALUMINA PHOTX A100

ALUMINA

ALUMINA

PHOTX A100

TETHON 3D’s A100 Resin is a fast-curing, high-purity alumina resin for core foundry & casting blades

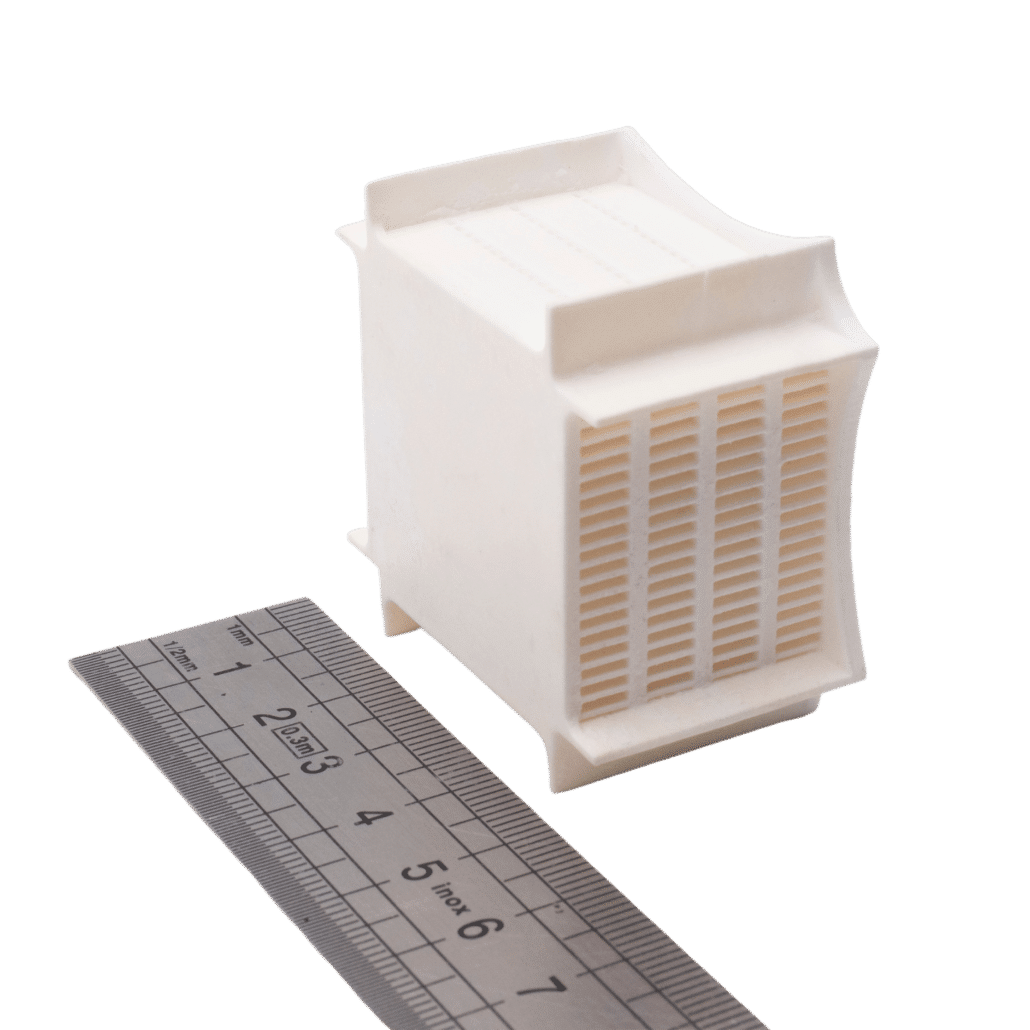

ALUMINA is the most widely used ceramic material with near limitless manufacturing capabilities. TETHON 3D’s A100 Resin is a fast-curing, high-purity alumina resin specifically designed for Ceramic DLP 3D printing. Years of engineering have enabled the development of both low and high viscosity versions, both of which exhibit very solid loading. Typical layer thickness is about 50 um, but thinner layers are possible, and the final surface finish is excellent. The minimum feature size is 0.150 mm, whether positive or negative, and the maximum wall thickness is 5 mm.