Specific applications of 3D printing in design, prototyping, and production for aerospace.

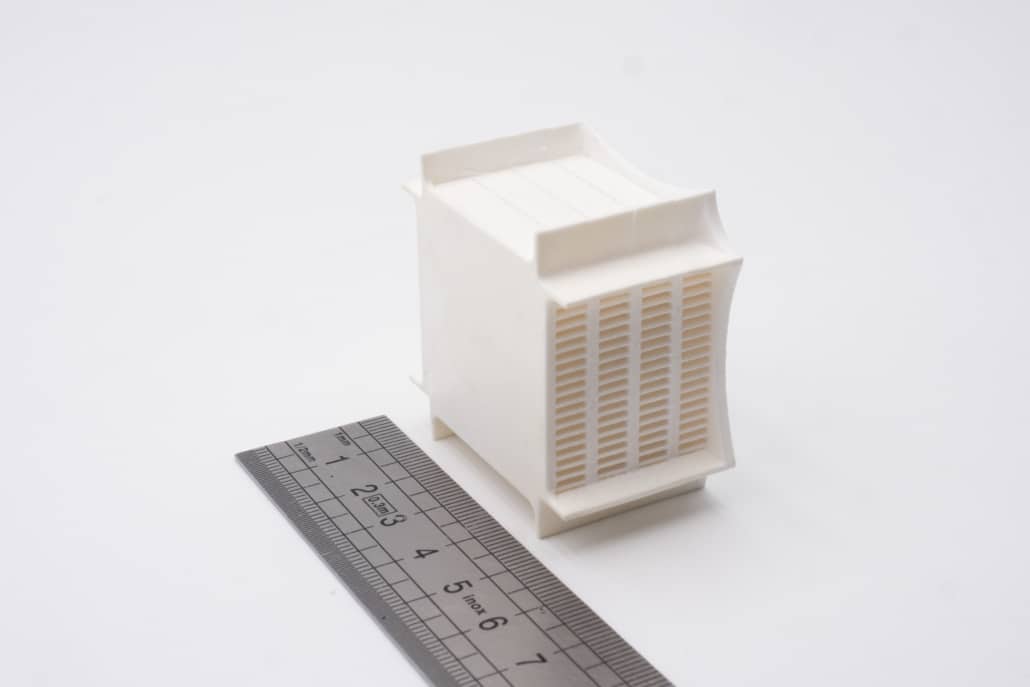

Prodways’ CERAM PRO series is ideal for small series production of ceramic parts, enabling the creation of intricate, lightweight designs for aerospace and robotics. 3D printing makes it possible to produce high-performance turbine cores, optical instruments, and other complex parts that traditional methods cannot.

By leveraging digital warehousing, manufacturers can print parts on demand, minimizing the need for large inventories and ensuring timely delivery of the right components. This capability offers significant cost savings and operational flexibility, keeping production agile in fast-paced industries where performance is paramount.