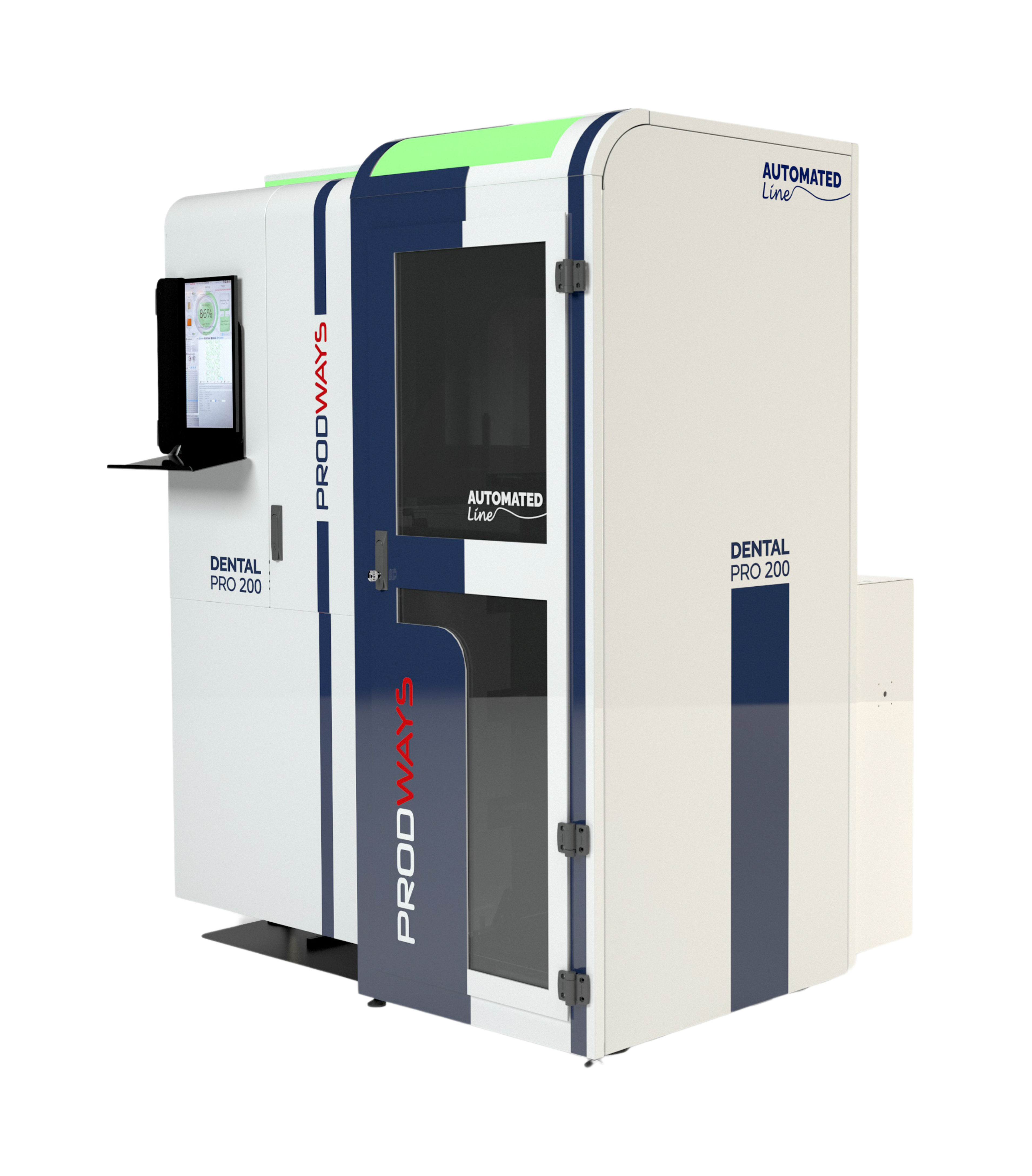

Prodways Machines is introducing its Automated Line at the International Dental Show (IDS) 2025 in Cologne, March 25-29. This new system is designed to streamline dental lab operations, offering continuous and fully automated production to make workflows smoother and more efficient.

Transform Dental Production with our Full Automation workflow

The DENTAL PRO Automated Line helps dental labs optimize production with a fully automated loader that keeps workflows running smoothly. Its rotating four-tray system ensures continuous, high-throughput production with minimal human intervention. Designed for efficiency, it delivers consistent, high-quality results every cycle, requiring little oversight. For exemple, in just four hours, it can produce up to 220 aligner models, making the process faster and more reliable.

This system enables zero-touch production, minimizing manual handling so your technicians can focus on high-value tasks and optimize labor costs. With real-time status updates, it offers complete control over the production process, reduces errors, and ensures smooth batch processing.

DENTAL PRO Series: Where Precision Meets Automation Excellence

Building on the success of the Dental Pro 3D Printer Range, the DENTAL PRO Automated Line boosts productivity by automating platform loading and print job management.

At the heart of this solution is the DENTAL PRO 3D Printer, featuring Prodways’ MOVINGLight® DLP technology for fast, precise, and high-volume dental production. With a single DLP® head, production runs fast, while the dual-head option boosts speed by up to 40%.

The high-speed rotating four-tray system optimizes workflow at critical production stages, with trays designed for seamless integration into post-processing devices for efficient batch handling. It supports a range of applications with our certified, in-house developed resins, designed to deliver perfect results with our machines and tailored to meet the specific needs of dental labs.