Renaissance Services relies on Prodways Technologies’ ProMaker L5000 3D printer for the establishment of its 3D Printing Division.

Renaissances Services, Inc. of Fairborn, an enterprise systems integrator that helps aerospace & defense companies deploy solutions to reduce cost and improve quality by integrating the management of the product lifecycle, supply chain, and product quality, has established a division that specializes in 3D printing and relies on Prodways Technologies’ ProMaker L5000 3D printer. The new group, known as the PERFECT-3D Division, performs a variety of 3D printing, using a range of materials, but specializes in printing of ceramic components, primarily for the investment casting industry.

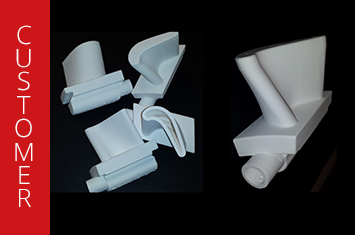

PERFECT-3D produces ceramic process aids in the form of cores, molds, and filters for use by foundries that produce investment castings for application across the aerospace and defense sector, including aircraft, engines, and support equipment. One area of particular interest is castings for “legacy” military systems; specifically those that were designed between the 1950s and 1990s that no longer have readily available sources for the castings used to produce key components such as gearboxes and housings.

Renaissance co-founder Robert Morris notes that Renaissance and PERFECT-3D have received a number of contracts from various military agencies to pursue ways to reduce the cost and lead time for these products. “For many of these castings there is scant technical data and the tooling no longer exists. New tooling typically costs six-figures and takes months to produce. We pursue a concept of ‘CAD as tooling’ to produce a ceramic mold using our own patent pending process. We then work with the foundry to produce a casting just like the original, filling a critical cost and lead time gap. We recently used our capability, working with a production foundry, to go from CAD model to a finished legacy engine gearbox casting in 26 days. This is a marked contrast from the two year lead times that we have heard about from the military sustainment community.”

PERFECT-3D Director of Operations Rick Pressley has been in the 3D printing industry since its infancy, including serving as manager of the 3D printing operation for a major jet engine producer. Pressley is quick to point out the difference between printing standard resins and ceramics: “With standard resins, we produce what is essentially a finished part, with limited post-processing. Ceramics are a whole different animal—less forgiving, with extensive post-processing, including sintering of the ceramic to achieve the final part. It’s a challenge, but we have demonstrated the ability to produce molds that make castings from various materials, including nickel-based alloys and aluminum. And we can cut the lead time for a mold from months to days. We use Prodways Technologies’ ProMaker L5000 3D printers to generate the ceramic molds. We purchased ProMaker L5000 serial number one from Prodways three years ago and have had a very successful relationship. In looking at equipment options for printing ceramics, we found the Prodways equipment to be the best value, offering leading edge technical capability and durability.”

This new announcement confirms Prodways Technologies 3D printers’ reliability for many years and major position as a key partner for innovative applications.